301 stainless steel sheet is a high strength austenitic steel with excellent corrosion resistance.

301 stainless steel sheet is a versatile austenitic steel with high strength and excellent corrosion resistance. Its primary alloying elements are chromium and nickel. It shows up in the aerospace, automotive, architecture, and transportation industries.

Advantages/Disadvantages

This stainless steel grade demonstrates excellent corrosion resistance, high strength, and good ductility. High hardness combined with high strength achieved through cold working make 301 suitable for structural applications in aircraft and its excellent corrosion resistance meet food service equipment standards. It can be easily formed and drawn. This grade is non-hardenable by heat treatment.

Applications

This steel grade is popular in a number of industries. This includes: food service, automotive, architecture, aerospace, and others.301 stainless is typically used in aircraft structural components, trailer bodies, trim for architecture and automotive, roof drainage, conveyor belts, train cars, appliances, cooking utensils, and more.

Treatment

It can be machined and welded, but not heat treated.

Product Parameters

| Product Name | Stainless Steel Sheet |

| Thickness | 0.25mm – 120mm, etc |

| Width | 10mm – 3,500mm, etc |

| Length: | 2000mm, 2438mm, 3000mm, 5800mm, 6000mm,12000mm, etc |

| Standard | ASME, AISI, ASTM, EN, BS, GB, DIN, JIS, etc. |

| Technology | Hot Rolled/Cold Rolled |

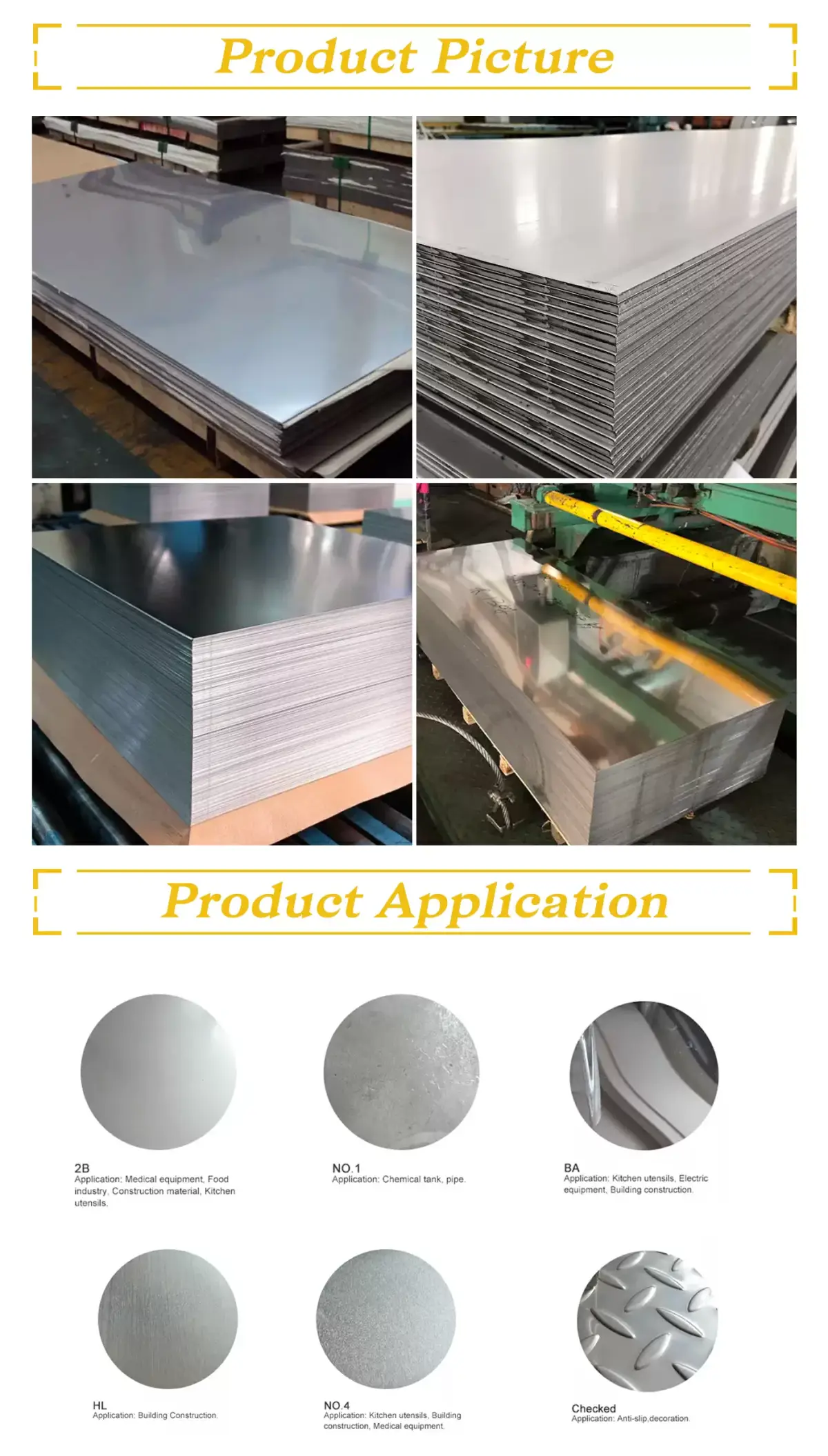

| Surface: | BA, 2B, NO.1, NO.2, NO.4, 4K, HL, Mirror, 8K |

| Application: | It is widely used in high-temperature and electric industry, medical devices, construction, chemistry, food industry, agriculture, and ship components.It also applies to food and beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs, and screen mesh etc. |

| Certification: | ISO, SGS,BV,CE,UL,etc |

| Technique: | Cold Rolled Hot Rolled |

| Edge: | Mill Edge Slit Edge |

| Tolerance | ±1% |

| MOQ | 1 ton |

| Supply Ability | 5000 tons / month |

| Lead Time | 7-15 working days after the receipt of 30% deposit |

| Payment Terms | 30%T/T Advance + 70% Balance |

| Price Terms | FOB, CFR, CIF, EXW |

| Packing | Standard sea-worthy package or as required |

Product Description

Stainless steel sheets are divided into two types: hot-rolled and cold-rolled, including 72938 thin cold plates with a thickness of 0.5.10-885 mm and medium and heavy plates with a thickness of 4.5-100 mm.

It is required to withstand the corrosion of various acids such as oxalic acid, sulfuric acid-ferric sulfate, nitric acid, nitric acid-hydrofluoric acid, sulfuric acid-copper sulfate, phosphoric acid, formic acid, acetic acid, etc. It is widely used in chemical industry, food, medicine, papermaking, petroleum, atomic energy, etc. Industry, as well as various parts and components of construction, kitchenware, tableware, vehicles, and household appliances.

In order to ensure that the mechanical properties such as yield strength, tensile strength, elongation and hardness of all kinds of stainless steel plates meet the requirements, the steel plates must undergo heat treatment such as annealing, solution treatment, and aging treatment before delivery. Special symbols 05.10 88.57.29.38.

The corrosion resistance of stainless steel mainly depends on its alloy composition (chromium, nickel, titanium, silicon, aluminum, manganese, etc.) and internal structure, and the main role is chromium. Chromium has high chemical stability and can form a passivation film on the steel surface to isolate the metal from the outside world, protect the steel plate from being oxidized, and increase the corrosion resistance of the steel plate. After the passivation film is destroyed, the corrosion resistance decreases.

There are two types of hot rolling and cold rolling according to the manufacturing method, and they are divided into 5 types according to the structural characteristics of the steel grade: austenite type, austenite-ferrite type, ferrite type, martensite type, and precipitation hardening type. It is required to withstand the corrosion of various acids such as oxalic acid, sulfuric acid-ferric sulfate, nitric acid, nitric acid-hydrofluoric acid, sulfuric acid-copper sulfate, phosphoric acid, formic acid, acetic acid, etc. It is widely used in chemical industry, food, medicine, papermaking, petroleum, atomic energy, etc. Industry, as well as various parts and components of construction, kitchenware, tableware, vehicles, and household appliances.

The stainless steel plate has a smooth surface, high plasticity, toughness and mechanical strength, and is resistant to corrosion by acids, alkaline gases, solutions and other media. It is an alloy steel that does not rust easily, but not absolutely rust-free.

Factory Tour