Product Parameters

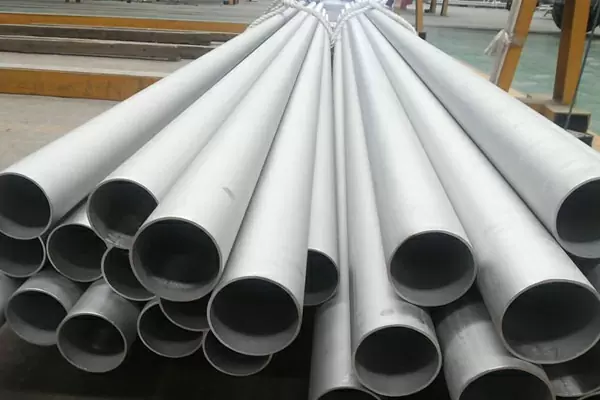

| Product Name | Stainless steel pipe |

| Type | Seamless or Welded |

| Material (ASTM) | 201 202 304 304L 309s 310s 316 316L 316TI 317L 321 904L S32205 |

| Material (DIN) | 1.4301 1.4306 1.4541 1.4401 1.4404 1.4571 1.4539 1.44621.4410 1.4833 1.4845 |

| Outter Diameter (OD) | 3-1220mm |

| Thickness | 0.5-50mm |

| Length | 6000mm 5800mm 12000mm or Customized |

| Surface Finished | No.1 No.3 No.4 HL 2B BA 4K 8K 1D 2D |

| End/Edge | Plain Mill |

| Technique | Cold Drawn or Hot |

| Standard | ASTM AISI DIN JIS GB EN |

| Certificate | ISO SGS |

| Package | Plywood Case/Pallet or Other Export Package Suitable for Long Distance Shipping |

Product Description

Stainless steel pipe is a kind of hollow long round steel, which is widely used in petroleum, chemical, medical, food, light industry, mechanical instrumentation and other industrial transportation pipelines and mechanical structural components. In addition, when the bending and torsional strength are the same, the weight is lighter, so it is also widely used in the manufacture of mechanical parts and engineering structures. [1] It is also commonly used as furniture and kitchenware.

Stainless steel pipes are divided into ordinary carbon steel pipes, high-quality carbon structural steel pipes, alloy structural pipes, alloy steel pipes, bearing steel pipes, stainless steel pipes, and bimetallic composite pipes, plated and coated pipes for saving precious metals and meeting special requirements. . There are many kinds of stainless steel pipes, different uses, different technical requirements and different production methods. The outer diameter of the currently produced steel pipe ranges from 0.1 to 4500mm, and the wall thickness ranges from 0.01 to 250mm. In order to distinguish its characteristics, steel pipes are usually classified as follows.

ways to produce

Stainless steel pipes are divided into two categories according to production methods: seamless pipes and welded pipes. Seamless steel pipes can be divided into hot-rolled pipes, cold-rolled pipes, cold-drawn pipes and extruded pipes. Cold-drawn and cold-rolled pipes are secondary Processing; welded pipes are divided into straight seam welded pipes and spiral welded pipes.

Section shape

Stainless steel pipes can be divided into round pipes and special-shaped pipes according to the cross-sectional shape. Special-shaped tubes include rectangular tubes, diamond-shaped tubes, elliptical tubes, hexagonal tubes, octagonal tubes and various asymmetrical tubes. Special-shaped tubes are widely used in various structural parts, tools and mechanical parts. Compared with the round tube, the special-shaped tube generally has a larger moment of inertia and section modulus, and has a larger resistance to bending and torsion, which can greatly reduce the weight of the structure and save steel.

Stainless steel pipes can be divided into equal-section pipes and variable-section pipes according to the shape of the longitudinal section. Variable section tubes include tapered tubes, stepped tubes and periodic section tubes.

Category of use

According to the application, it can be divided into oil well pipe (casing, oil pipe and drill pipe, etc.), line pipe, boiler pipe, mechanical structure pipe, hydraulic prop pipe, gas cylinder pipe, geological pipe, chemical pipe (high pressure fertilizer pipe, oil cracking pipe) ) and marine pipes, etc.

Factory Tour